Clean fuel performs better than dirty fuel. Dirt, dust, and grime can get into your fuel and seriously damage your vehicle’s engine. It's fairly obvious those materials pose a risk, but did you know that water is also considered to be a very dangerous contaminant of fuel?

When water enters a vehicle’s fuel supply, the vehicle will noticeably sputter or stall. This is due to diluted fuel reaching the fuel injectors or carburetors, pumping the vehicle’s engine with a weakened power source.

This is considered to be a "best-case scenario" of water contamination. Did you know that water can do irreparable damage to your vehicle? Even a small amount of water in your fuel tank can ruin the electric fuel pump, clog up the fuel lines, rust the interior of the tank, and cause fuel injector tips to explode.

The stakes are even higher with jet fuel. Water separates from jet fuel; and once the aircraft is in flight, the lower temperatures of the upper atmosphere can cause those separated water droplets to freeze. These frozen water droplets can block fuel intake lines, resulting in malfunction or even a crash.

Related article: Superabsorbent Polymers in Meat Packaging

Superabsorbent Polymers in Fuel Filtration

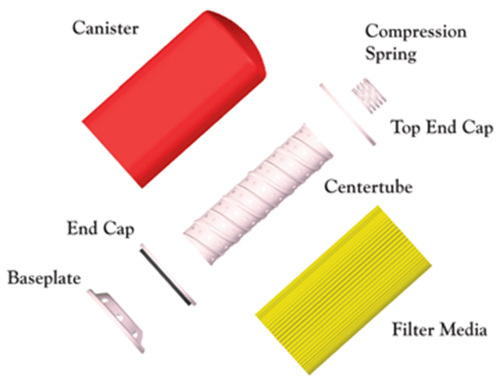

So how do we prevent water from entering our fuel supply and possibly causing one of the problems listed above? There are several methods, but one of the most simple and cost-effective solutions is using a filter. Below is an illustration of a basic filter.

![]() Image: Deconstructed view of a fuel filter

Image: Deconstructed view of a fuel filter

The yellow part labeled “Filter Media” is just that: a porous, paper-like substance that is designed to catch any solid particles above a certain size that are deemed harmful. This filter media can also be constructed using superabsorbent polymers impregnated material to catch any free water that passes through it. Since superabsorbent polymers (SAPs) do not absorb fuel, the fuel itself will pass through the filter undeterred.

This is a very different type of application from the powdered SAPs we usually talk about when discussing remediation and liquid waste management. So this is definitely one of the more “behind-the-scenes” uses of SAPs. But we are willing to bet that the next time you are filling your car up with gas, or sitting in an airplane about to take off, fuel filtration might cross your mind.

Related Article: Superabsorbent Polymers in Ice Packs

For more information on how superabsorbent polymer technology can help you save your and your clients’ time, money, and risk; please contact Whit Rawls at wrawls@chasecorp.com.