Zappa Stewart supplies a wide range of SuperAbsorbent Polymers (SAPs). Most SAPs are surface cross linked (referred to as SXM) and are widely used in diapers and hygiene products. However, there are also non-surface cross linked SAP’s (often referred to as pre-surface crosslinked or PSXM for short) that have unique properties and are well suited for specific applications.

Zappa Stewart supplies a wide range of SuperAbsorbent Polymers (SAPs). Most SAPs are surface cross linked (referred to as SXM) and are widely used in diapers and hygiene products. However, there are also non-surface cross linked SAP’s (often referred to as pre-surface crosslinked or PSXM for short) that have unique properties and are well suited for specific applications.

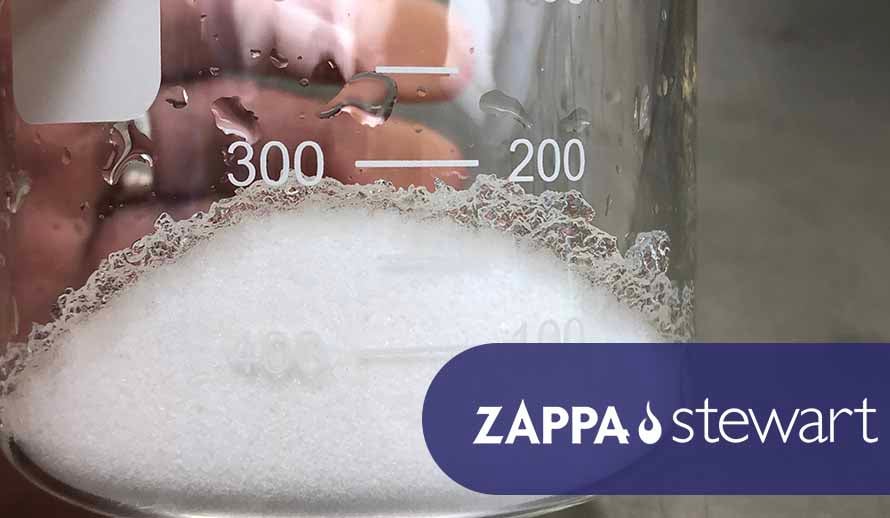

Sodium polyacrylate superabsorbent polymers are produced by chemically bonding (cross linking), many acrylic acid molecules into a larger chain (polymer) with a sodium neutralizer which is then crushed up or formed into particles. This base product is internally cross linked but with no additional outer surface cross linking and therefore is non or pre-surface cross linked material (PSXM). Much of the SAP produced then goes through a secondary chemical reaction to bond or further cross link the outer surface resulting in surface cross linked material (SXM). This secondary cross-linking process adds unique properties to the SAP material including particle shape retention during and after absorption which allows the SAP to more homogeneously absorb fluid in a diaper or other fluid absorption application.

Image: Surface Cross-linked Sodium Polyacrylate SAP (left); SAP with No Surface Cross-linking (right)

While many superabsorbent applications require SXM technology, there are certain applications in which PSXM technology is preferred. The incredibly fast absorption speed coupled with the unique surface properties of PSXM SAPs allows the outer layer of SAP to rapidly absorb fluid, swell, and form a water-blocking wall, or crust, of SAP particles. The external “wall” of swollen SAP particles limits, or prevents, the flow of the fluid into the internal mass of still-dry SAP particles. The water blocking capability of PSXM SAP technology is widely utilized in the electrical and fiber optic cable industry to protect sensitive cable assets from costly water infiltration damage.

Related Article: SAP Absorption Speed vs. Permeability for Waste Solidification

Another important market for PSXM SAP technology is for the manufacturing of temperature-regulating gels used in cold packs, heat packs, and other hydrated gel packs. Consumers of these products often prefer the smooth gel texture provided by the non-defined particle structure of the PSXM materials. While both SXM SAP and PSXM SAP exhibit extremely high absorbency and the ability to retain liquid under pressure (i.e. not leak when the icepack is punctured), hydrated gel pack applications often prefer the smooth, non-defined particle structure of PSXM SAP technology.

If you find yourself in need of a high performance absorbent material, please contact Zappa Stewart to discuss your application requirements. From our wide selection of both SXM and PSXM feedstock materials, we can customize a product specific to your application.