Superabsorbent polymers (SAP) are used globally for a wide range of hygiene, industrial, environmental, medical, and consumer applications. Sodium polyacrylate SAPs, in particular, are the absorbent workhorse of the modern baby diaper, many industrial waste treatment processes, and medical waste solidification. Even with all of the different ways that SAPs help millions of people each day to live safer, healthier, cleaner, and more convenient lives, there are still a number of misconceptions about SAPs.

Superabsorbent polymers (SAP) are used globally for a wide range of hygiene, industrial, environmental, medical, and consumer applications. Sodium polyacrylate SAPs, in particular, are the absorbent workhorse of the modern baby diaper, many industrial waste treatment processes, and medical waste solidification. Even with all of the different ways that SAPs help millions of people each day to live safer, healthier, cleaner, and more convenient lives, there are still a number of misconceptions about SAPs.

Myth #1: SAPs are expensive.

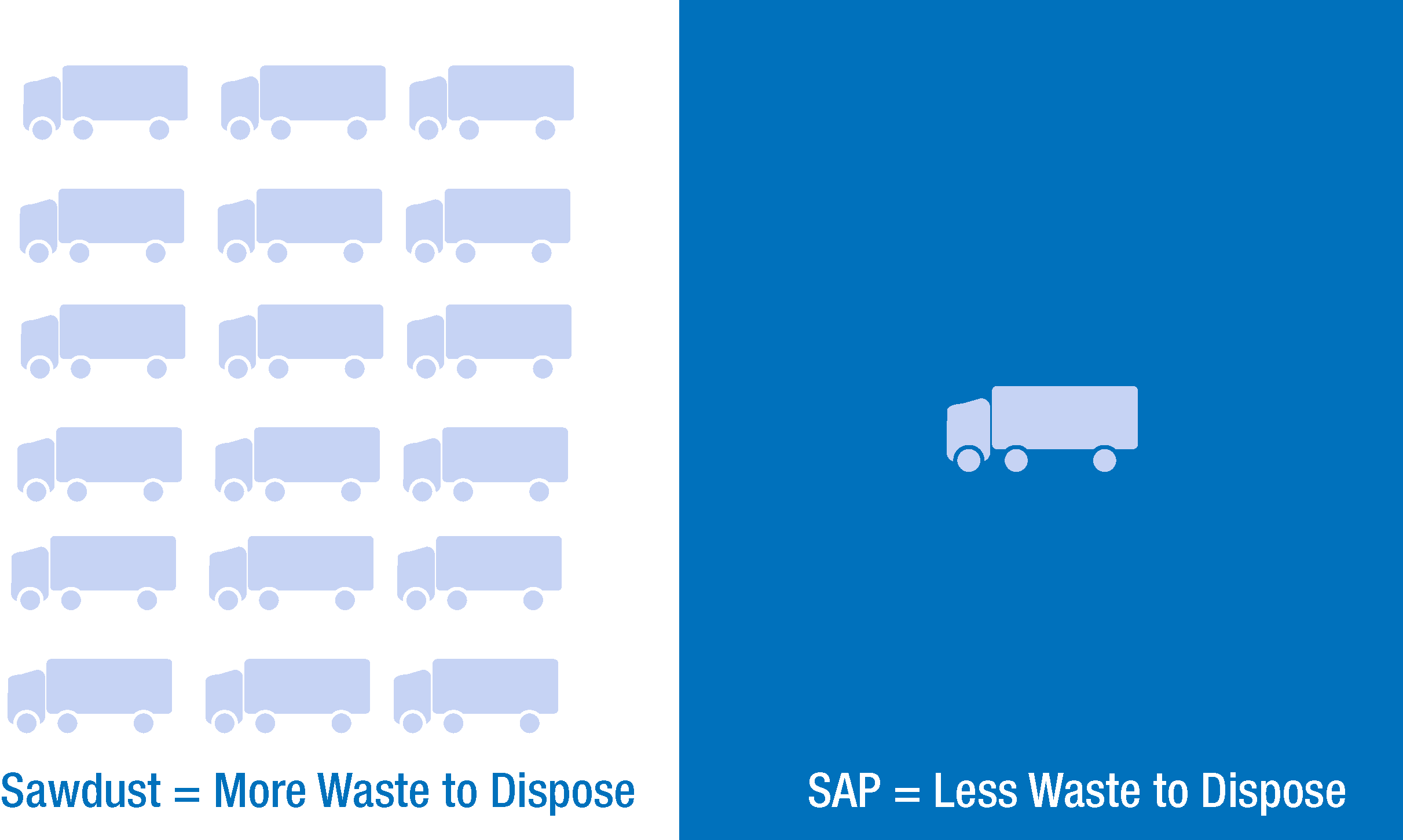

While the unit cost of Superabsorbent polymers (SAPs) is higher than that of traditional absorbents (sawdust, cement, fluff, etc.), SAPs feature far superior absorbency, meaning SAPs are more efficient with, very low dosage rates (0.5% - 1.5%, by weight) typically required to solidify a liquid-bearing waste stream.

Cement is often applied at dosage rates of 10%-25% (by weight). The absorbency of sawdust is so low that dosages of 100%-200% (by weight) are often needed to solidify liquid-bearing waste.

In summary, SAPs can eliminate free liquid in a liquid waste stream with 10-25 times less reagent than cement and up to 200 times less material than sawdust. Remember, if a ton of sawdust is added to a ton of waste, you will pay to dispose of 2 tons at a landfill (waste plus the sawdust). High efficiency superabsorbent polymers minimize the amount of waste disposed at the landfill which minimizes project costs. SAPs are not expensive, they are cost effective.

Myth #2: SAPs create a jelly or slime-like texture when hydrated

So many unscientific solidification tests have been conducted with SAP in a cup of tap water that it can give some the wrong visual of SAP-treated waste texture. While a pure water waste stream treated will result in a fairly gelatinous texture, most waste treatment processes involve slurries or high solids sludges and muds. The solids content of a liquid-bearing waste stream adds a granular texture to an SAP-treated waste resulting in a texture similar to dry, stackable soil. But even when treating pure water, the appropriate SAP product will typically produce a treated material that can pass paint filter and be disposed of at a landfill.

So many unscientific solidification tests have been conducted with SAP in a cup of tap water that it can give some the wrong visual of SAP-treated waste texture. While a pure water waste stream treated will result in a fairly gelatinous texture, most waste treatment processes involve slurries or high solids sludges and muds. The solids content of a liquid-bearing waste stream adds a granular texture to an SAP-treated waste resulting in a texture similar to dry, stackable soil. But even when treating pure water, the appropriate SAP product will typically produce a treated material that can pass paint filter and be disposed of at a landfill.

Myth #3: SAPs are effective only by themselves.

SAPs are inert, so they do not chemically react with most other products. SAPs can be customized to achieve specific performance goals. Need to transform wet, sloppy soil or CCR (coal ash) into a dry solid with a compressive strength criterion? SAPs have been successfully applied with cementious materials. Need to solidify and prevent microbial growth? SAPs containing granular chlorine-compounds are widely used in industrial and healthcare settings in which spread of infectious agents is possible or likely. Need to solidify and reduce leachable contaminants? SAPs are mixed with reactive mineral products like magnesium oxide to stabilize heavy metals. SAPs are an excellent standalone technology but can also enhance, or be enhanced by, other materials’ functionality.

|

|

| Zappa-Stewart’s P2 Blend (SAP+Bentonite) | Zappa-Stewart’s P6 Blend (SAP+wood flour) |

Myth #4: SAPs are toxic

Of all the myths about SAPs this one may be the easiest to dispel. As mentioned previously, sodium polyacrylate SAPs provide the absorbent functionality of the modern baby diaper and many other personal hygiene products that are designed to make intimate contact with human skin and tissues.

Of all the myths about SAPs this one may be the easiest to dispel. As mentioned previously, sodium polyacrylate SAPs provide the absorbent functionality of the modern baby diaper and many other personal hygiene products that are designed to make intimate contact with human skin and tissues.

In addition to hygiene uses, sodium polyacrylate SAPs are also approved by the United State Food & Drug Administration (FDA) as an indirect food additive. The absorbent pads that remove excess fluid from the surface of meat are packed with SAPs. Not only are SAPs not toxic, but in fact SAPs prevent the spread of foodborne pathogens by absorbing liquid from food which could otherwise spoil.

Myth #5: SAPs are a silver bullet.

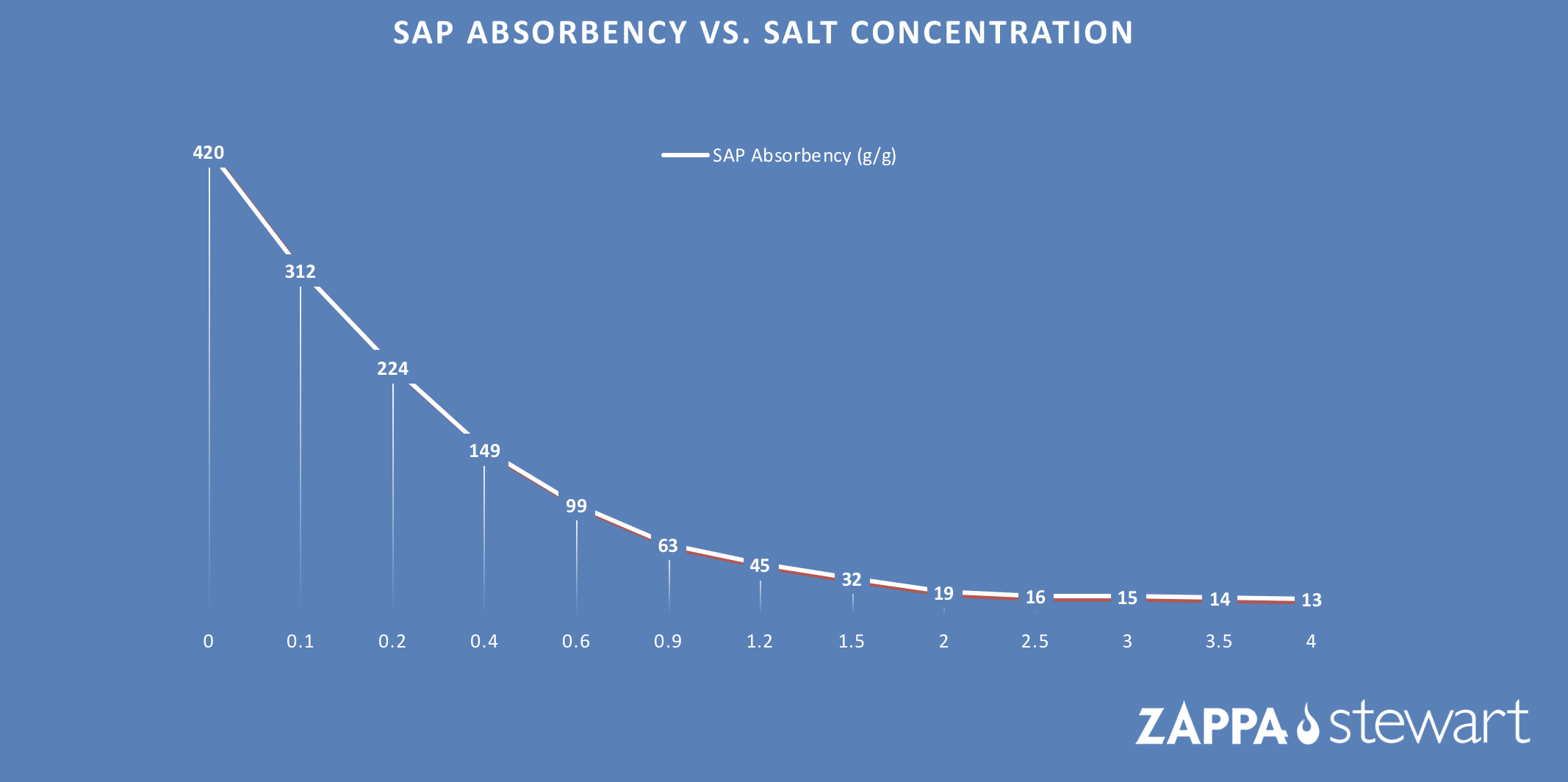

SAPs are versatile, efficient, safe, and always available but SAPs are not the answer for all waste streams. High concentrations of salt or brine and extreme pH (less than 2.0 and greater than 12.0) severely decrease the absorbency of SAP. It’s wise to test the pH and salt concentration of a waste stream before attempting to solidify with SAP.

Superabsorbent polymers have been improving lives all over the world for decades and new innovations in SAP technology are constantly being developed. Despite some misconceptions, SAPs are highly cost effective and safe absorbents materials that are used to improve a wide and diverse array of liquid-absorption applications. For more information on SAP technologies or to discuss a potential SAP application with our technical team, please contact Whit Rawls at 828.320.4615 or wrawls@chasecorp.com.